What is Lap Winding?

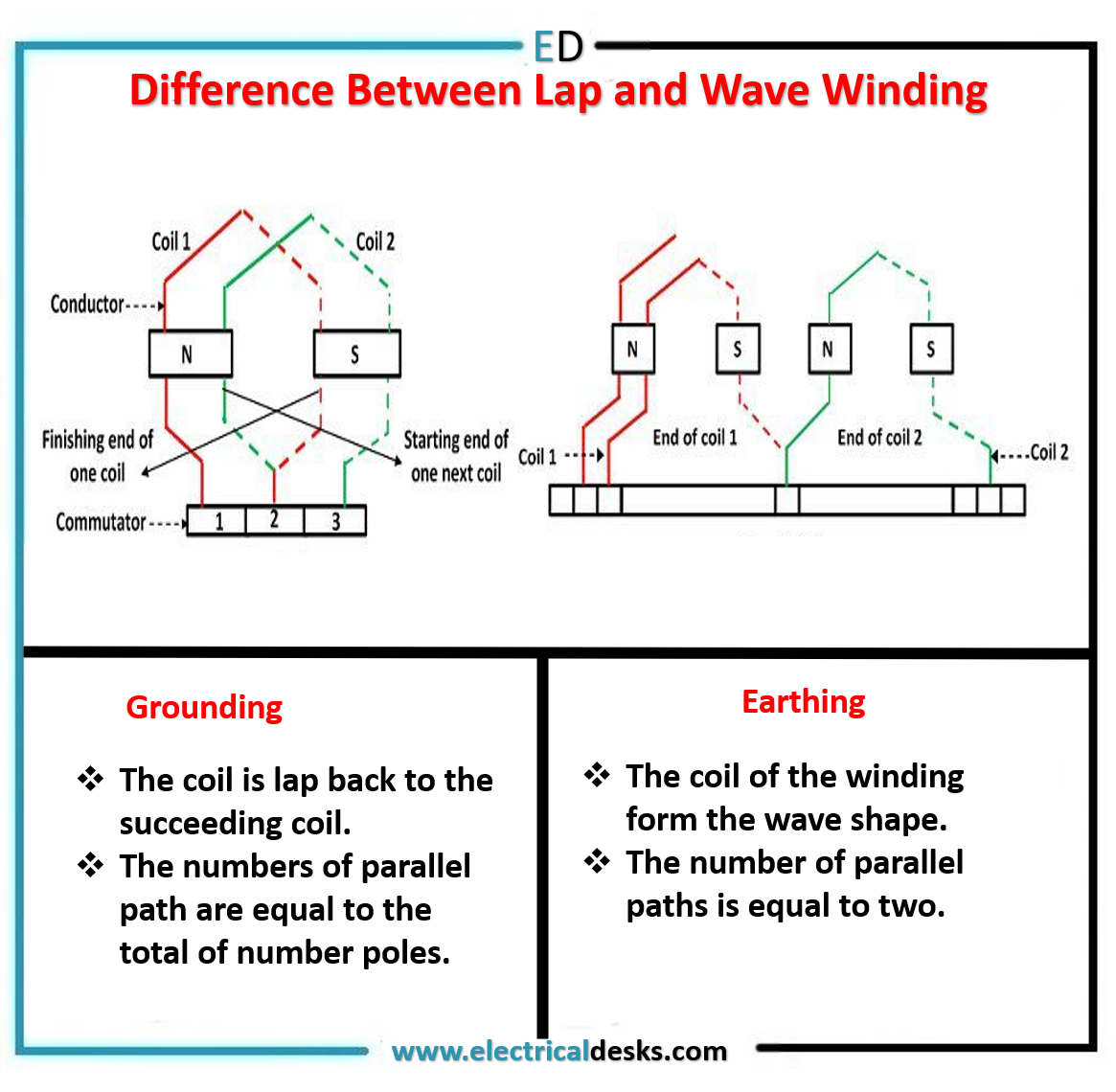

The one end of the armature coil is connected to the one segment of the commutator and the second end of the first coil and first end of the second coil are placed on the same segment of the commutator.

What is Wave Winding?

In wave winding, one end of the first armature coil is connected to the starting end of the second coil and which have the same polarity. In wave winding, winding is connected to wave shape so these windings are called wave windings.

Comparison Chart

| Lap Winding | Wave Winding |

|---|---|

| In lap Winding, the number of parallel paths which is denoted by A is equal to the number of poles which is denoted by P where A =P. | In wave winding, the number of parallel paths equals to 2. |

| In lap winding, the number of carbon brushes is equal to the number of poles. | In wave winding, the number of carbon brushes is equal to 2 because the number of parallel paths in wave winding is equal to 2. |

| In lap winding, Equilizer rings are required for better commutation and balancing the potential difference in carbon brushes. | In wave winding, Equilizer rings are not required because only two carbon brushes are used. |

| The lap windings are used in low voltage and high current machines. | The wave windings are used for high voltage and low current machines. |

| In lap winding, emf generated in coils are independent of a number of poles. | In wave windings, the emf generated in coils depends upon the number of poles. |

| In lap winding, the line current in each parallel path is (line current/number of parallel paths). | In wave winding, the line current in each parallel path is (line current/2). |

| In lap winding, the commutator pitch(distance between two commutator segments where two ends of one armature coil are connected) is equal to 1. | In wave winding, the commutator pitch(distance between two commutator segments where two ends of one armature coil are connected) is equal to 2. |

| The lap windings are fewer advantages than wave windings. | The wave windings are more efficient and have more advantages than the lap windings. |

| The lap windings are more costly because the equalizer rings and more carbon brushes are used. | The cost of wave windings is very cheap. |

| In lap windings, the equalizer rings are used. | In wave windings, dummy coils are used. |

| The efficiency of lap windings is less. | The efficiency of wave windings is more. |

| The lap winding is called parallel winding or multiple windings. | The wave windings are called two circuit or series windings. |

| In lap windings, the emf produced is less. | In wave windings, the emf produced is more. |

| In lap windings, the end of the armature coils is connected to the adjacent segment of the second coil on the commutator. | In Wave windings, the end of armature coils is connected to commutator segments from some distance apart. |

| In lap windings, the armature coils are laps back towards the succeeding armature coils. | In wave windings, the armature coils form a wave shape. |

| The simplex windings, duplex windings and triplex windings are types of lap windings. | The progressive and retrogressive are types of wave windings. |

| In lap windings, the equalizer rings are used for balancing the potential difference in armature coils and reducing the load on loaded carbon brushes. The equalizer rings are electrically connected to the lap windings coils. | In wave windings, the dummy coils are used for providing a mechanical balance to the machines. The dummy coils are not connected electrically to the wave windings coils. |

Key Difference between the lap winding and wave winding

1. In lap Winding, the number of parallel paths which is denoted by A is equal to the number of poles which is denoted by P where A =P. In wave winding, the number of parallel paths equals to 2.2. In lap winding, the number of carbon brushes is equal to the number of poles. In wave winding, the number of carbon brushes is equal to 2 because the number of parallel paths in wave winding is equal to 2.

3. In lap winding, Equilizer rings are required for better commutation and balancing the potential difference in carbon brushes. In wave winding, Equilizer rings are not required because only two carbon brushes are used.

4. The lap windings are used in low voltage and high current machines. The wave windings are used for high voltage and low current machines.

5. In lap winding, emf generated in coils are independent of several poles. In wave windings, the emf generated in coils depends upon the number of poles.

6. In lap winding, the line current in each parallel path is (line current/number of parallel paths). In wave winding, the line current in each parallel path is (line current/2).

7. In lap winding, the commutator pitch(distance between two commutator segments where two ends of one armature coil are connected) is equal to 1. In wave winding, the commutator pitch(distance between two commutator segments where two ends of one armature coil are connected) is equal to 2.

8. The lap windings are fewer advantages than wave windings. The wave windings are more efficient and have more advantages than the lap windings.

9. The lap windings are more costly because the equalizer rings and more carbon brushes are used. The cost of wave windings is very cheap.

10. In lap windings, the equalizer rings are used for potential difference balance. In wave windings, dummy coils are used.

11. The efficiency of lap windings is less. The efficiency of wave windings is more.

12. The lap winding is called parallel winding or multiple windings. The wave windings are called two circuit or series windings.

13. In lap windings, the emf produced is less. In wave windings, the emf produced is more.

14. In lap windings, the end of the armature coils are connected to the adjacent segment of the second coil on the commutator. In Wave windings, the end of armature coils is connected to commutator segments from some distance apart.

15. In lap windings, the armature coils are laps back towards the succeeding armature coils. In wave windings, the armature coils form a wave shape.

16. The simplex windings, duplex windings and triplex windings are types of lap windings. The progressive and retrogressive are types of wave windings.

17. In lap windings, the equalizer rings are used for balancing the potential difference in armature coils and reducing the load on loaded carbon brushes. The equalizer rings are electrically connected to the lap windings coils. In wave windings, the dummy coils are used for providing a mechanical balance to the machines. The dummy coils are not connected electrically to the wave windings coils.