Equalizer Rings

The Equalizer rings are used in the lap winding of dc machines. In lap windings, the total number of the parallel path(A) is equal to the total number of poles(P).

Under Ideal conditions, The magnetic flux produced in all the poles is equal. The induced emf in all poles and the current produced due to induced emf are the same in all the parallel paths.

Under practical operating conditions, air gap length and magnetic properties of poles material are differed and cause unbalance of induced emf in various parallel paths. Hence the coil conductors under stronger magnetic flux generate stronger induced emf and generate a larger current than the remaining conductor in the winding.

Due to this problem, some brushes on the commutator carry more current and get overloaded and some brushes carry less current and get underloaded. In the given commutator time period current in brushes can not reverse due to the overloaded brushes and speaking take place between the brushes and the commutator surface. To overcome this problem equalizer rings are used in lap windings.

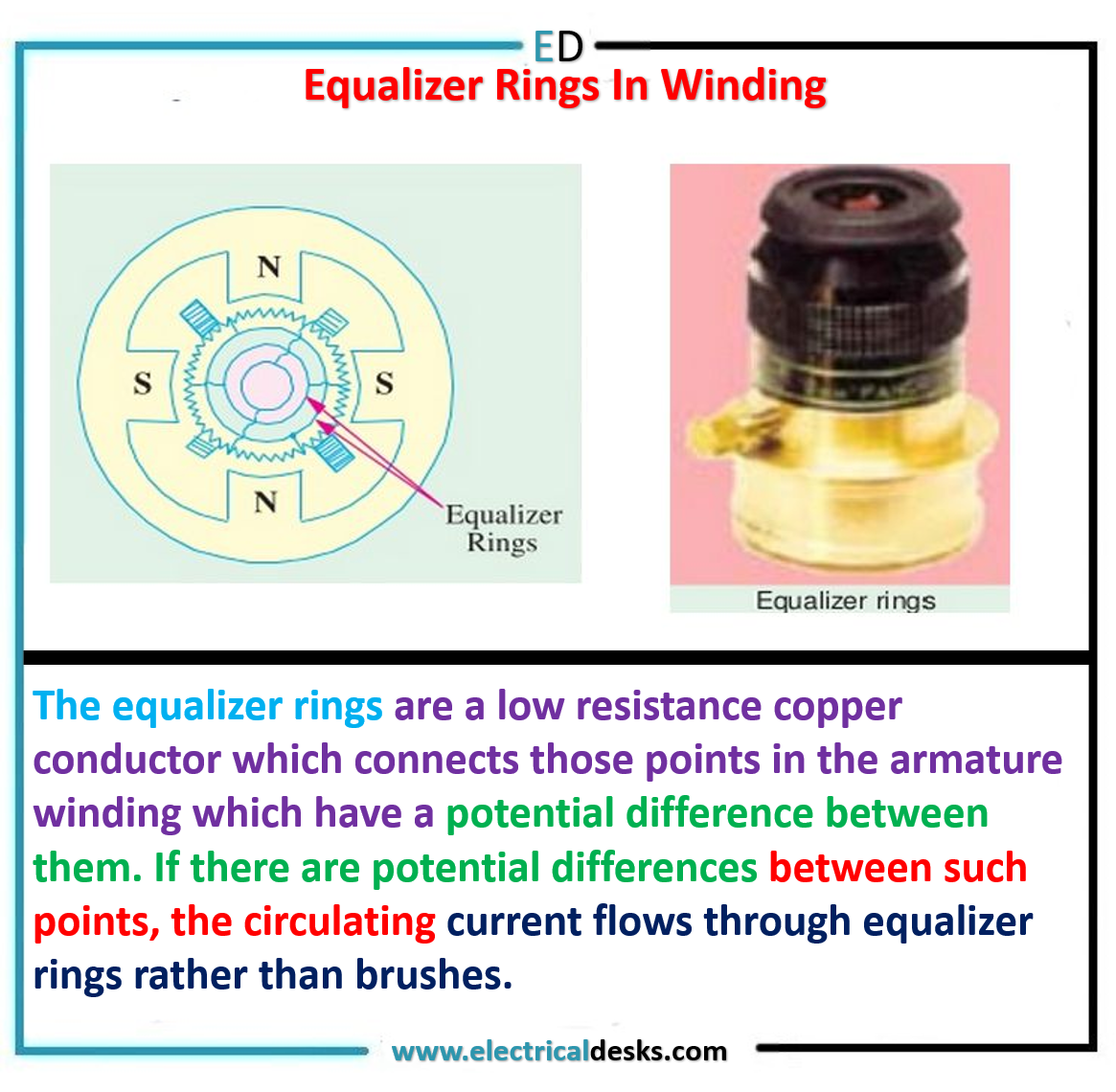

The main function of equalizer rings (which are made from copper and have low resistance) is to reduce the unequal current distribution in the armature coils conductor and reduce the sparking between the carbon brushes and commutator surface.

The equalizer rings are low resistance rings which are made from copper conductors. The equalizer rings are connected between the points of armature winding which have potential differences.

The excess circulating current flows through the equalizer rings. This circulating current can not be flowing through the armature winding coils and sparking does not take place between the carbon brushes and the surface of the commutator.

The equalizer rings are only required in lap winding and not required in wave winding because lap windings have more number of parallel paths than wave winding. In higher ratting machines less than 20 nos of equalizer rings are used.